DARDI is dedicated to the design and manufacturing of waterjet cutting machines and is backed by more than 20 years of experience. This allows us to offer our customers practical, high-performance waterjet cutting machines for clients in a diverse array of industries

Our waterjet cutting machines come in a variety of configurations. They carry out both water only waterjet cutting and abrasive waterjet cutting. These machines can also work in conjunction with abrasive metering feeders and abrasive removal systems for a highly efficient, abrasive waterjet cutting performance

Users can customize the waterjet cutting machines according to their requirements. We also offer standard waterjet cutting machines for customers to choose from.

-

- 3-Axis Waterjet Cutting

The 3-axis waterjet cutting machine completes two-dimensional cutting, including horizontal and vertical cutting.

- DWJ1313 Flying Bridge Style 3-Axis Waterjet Cutting Machine

- DWJ1525 Flying Bridge Style 3-Axis Waterjet Cutting Machine

- DWJ2040 Flying Bridge Style 3-Axis Waterjet Cutting Machine

- DWJ2060 Flying Bridge Style 3-Axis Waterjet Cutting Machine

- DWJ2080 Flying Bridge Style 3-Axis Waterjet Cutting Machine

- DWJ3060 Gantry Style 3-Axis Waterjet Cutting Machine

- DWJ30100 Gantry Style 3-Axis Waterjet Cutting Machine

- DWJ46126 Gantry Style 3-Axis Waterjet Cutting Machine

-

- 5-Axis Waterjet Cutting The 5-axis waterjet cutting machine features an A-axis (angle and perpendicular) and C-axis (rotation around the Z-axis) that opens it up to 3D cutting abilities. Equipped with a 5-axis cutting head, it can cut cones, drill holes in tubes, and produce rubbed and beveled edges.

-

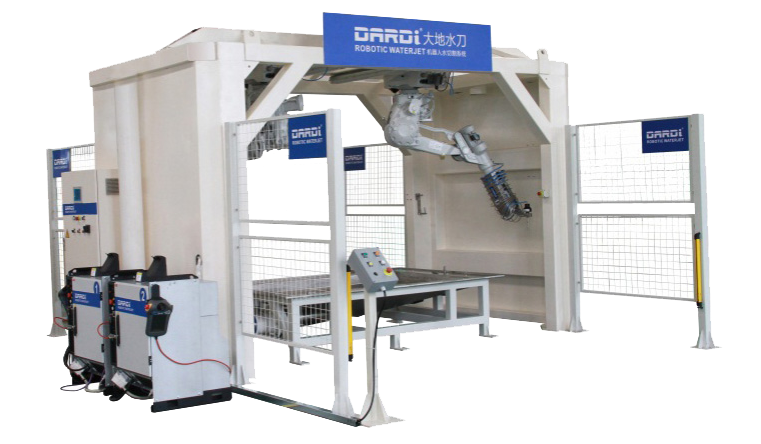

- Robotic Waterjet Cutting

DARDI integrated waterjet cutting systems and robotic arms for a robotic waterjet cutting.

Our robotic waterjet cutting machine is equipped with a 6 axis robot arm and waterjet intensifier pump with the power source. It uses pure water to cut edge contours and drill holes, as well as separate workpieces from scrap metal, all in a single, continuous session.- DRW-Fix Robotic Waterjet Cutting Machine

- Rotary Robotic Waterjet Cutting Machine

- DRW-Multi Robotic Waterjet Cutting Machine

-

Tested Quality

Our waterjet cutting machines have been sold to customers in more than 50 countries and regions and approved by more than 7,000 clients.

-

Long-Term Durability

Our waterjet cutting machines are created for long-term use. Their industrial-grade components are manufactured here in-house using precision machining and expert, strict quality inspection.

-

Full Service

We provide full service for our machines so as to provide convenience and safety for your use. Our service includes on-site installation and commissioning, 12 months warranty period, equipment upgrades and retrofits, long term supply of accessories, etc.

-

Engineered to Order

DARDI has extensive experience in the design and manufacturing of waterjet cutting machines, giving us the ability to manufacture custom made waterjet cutting machines to meet specific customer requirements. As an example, we can customize waterjet cutting machines for food industries, large format waterjet cutting machines, highly integrated robotic waterjet cutting systems and more.

Simply share your material needs for cutting and your processing requirements, and our team will work with you to ensure a full understanding of all requirements, then design the best waterjet cutting machine for your application needs.

-

Why Waterjets

Waterjet cutting is the most applicable cutting method for processing metal materials and non-metallic materials, industrial materials, food materials, artificial materials and natural materials as it easily cuts materials that are otherwise hard to process, such as composite materials and refractory metals.

Waterjet cutting is an exceptionally safe cutting method as it creates no heat-affected zones and will not damage the cutting material. It features a number of advantages compared to other processing methods, including a smooth, clean cutting edge, and the ability to cut nearly anything with no resulting smoke, dust, vapor, or gasses produced.

Benefits of Waterjet Cutting- Waterjet cutting can cut almost everything, including different types of metal and non-metal materials. It also easily cuts special materials, such as composite materials and refractory metals.

- Waterjet cutting is a cold process that creates no heat affected zones, as well as provides a smooth cut that requires no secondary processing.

- It can cut curves and penetration according to customer needs with no need for additional molds.

- The cutting gap of waterjet cutting is only 1mm. The cut edge is smooth with a roughness between 1.6µm~3.2µm

- The workpiece requires no special clamping, and operation is simple and convenient.

- It provides a wide cutting range with the ability to cut metal as thick as 200mm.

- Waterjet cutting machines work in conjunction with machining centers to complete a variety of processes, including drilling, cutting, bevel cutting, and more.

-

- Email: sales@dardiwaterjet.com

- Contact: Mr. Gao

- Mobile: +86-18851630918

-

Products

-

Waterjet Cutting Solution

-

Waterjet Cutting System Part